Power Plant Solutions – Consultancy

In today’s rapidly evolving Power Plant Solutions – Consultancy, energy landscape, power generation solutions need to be efficient, sustainable, and reliable. As a leading power plant consultant, we specialize in delivering comprehensive solutions that optimize plant performance, enhance operational efficiency, and ensure compliance with environmental regulations.

Understanding Power Plant Solutions

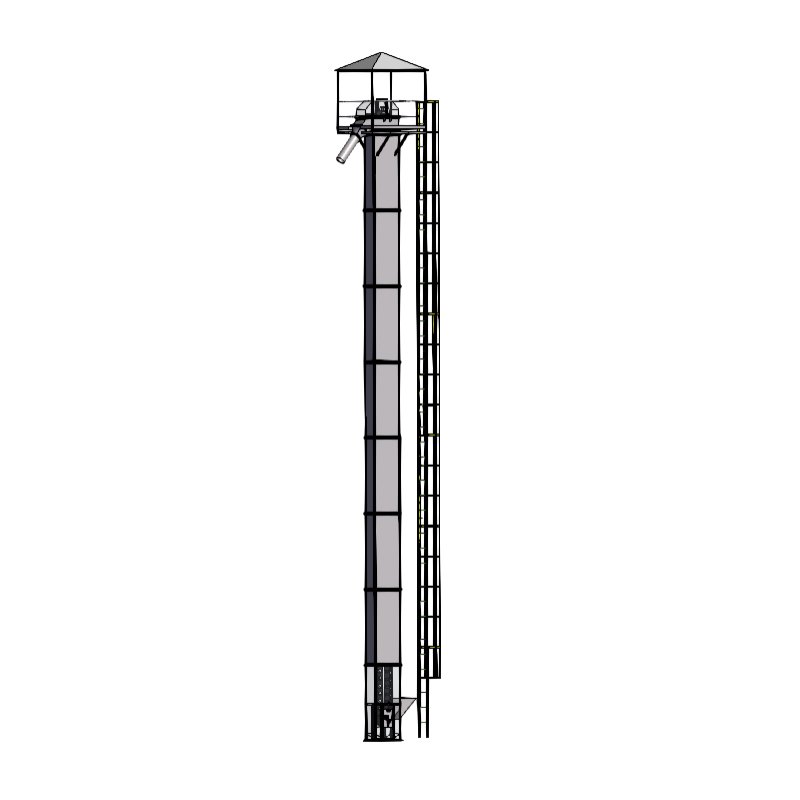

Power plant solutions encompass a wide range of services, from design and engineering to commissioning, operation, and maintenance. These solutions are tailored to meet the specific requirements of different industries, ensuring seamless energy generation and distribution.

Key Components of Power Plant Solutions

Feasibility Studies and Project Planning

> Site selection and assessment

> Fuel source evaluation (coal, gas, biomass, renewables)

> Environmental impact analysis

> Financial viability and cost estimation

Engineering, Procurement, and Construction (EPC)

> Conceptual and detailed plant design

> Equipment procurement and supplier evaluation

> Civil, mechanical, and electrical engineering solutions

> Project management and execution

> High-efficiency boiler designs for reduced fuel consumption

> Steam turbine selection and optimization

> Waste heat recovery systems

> Emission control technologies

Automation and Digitalization

> SCADA and DCS integration for real-time monitoring

> AI-driven predictive maintenance

> IoT-enabled performance analytics

> Smart grid and load management solutions

Operations and Maintenance (O&M)

> Routine maintenance and troubleshooting

> Performance monitoring and optimization

> Workforce training and skill development

> Spare parts management and upgrades

Energy Efficiency and Sustainability

> Renewable energy integration (solar, wind, biomass)

> Carbon capture and emission reduction strategies

> Water and waste management solutions

> Compliance with national and international standards

Why Choose Us for Power Plant Solutions – Consultancy?

As an experienced power plant consultant, we offer customized solutions tailored to industry needs. Our expertise in cutting-edge technology, regulatory compliance, and operational excellence makes us the preferred choice for power plant solutions.

By leveraging innovative engineering techniques, data-driven insights, and sustainable practices, we ensure that your power plant operates at peak efficiency while minimizing environmental impact.